Third Party Inspection

Third Party Inspection

Third Party Inspection

Third Party Inspection

Conventional NDT Services

Welcome to our Conventional NDT Services page, where we provide top-quality Non-Destructive Testing (NDT) services for plant inspections. Our conventional NDT methods include Magnetic Particle Testing, Ultrasonic Testing, Radiographic Testing, and Liquid Penetrant Testing.

Our experienced technicians are trained to utilize state-of-the-art equipment to provide accurate and reliable inspection results. Our services are designed to help ensure the safety and reliability of your plant equipment while minimizing downtime and maintenance cost

Have a Question?

Our conventional NDT services are suitable for a wide range of industries, including oil and gas, power generation, petrochemical, and more.

Contact us today to learn more about how our conventional NDT services can help you maintain the safety and efficiency of your plant equipment.

Who we work with?

Our LOLER inspection services cover a wide range of industries including:

- Oil and Gas Industry

- Petrochemical Industries

- Refining & Processing plants

- Fertilizers

- Power Generation

- Water

- Manufacturing

- Fabrication and Heavy Construction Industries

- Construction Industry

- Shipyard

- Aerospace

- Automotive

Services

- Third Party Inspection

- Specialized Manpower Services

- Conventional NDT Services

- Advanced NDT Services

- Pre / Post Weld Heat Treatment Services

Other Services

- Positive Material Identification (PMI)

- Ferrite Measurement

- Holiday Inspection

- Paint or Coating thickness measurement.

- Hardness Testing

Ultrasonic Testing (UT)

Thickness measurements and wall mapping for corrosion, flaw detection of piping, pressure vessels, structural parts.

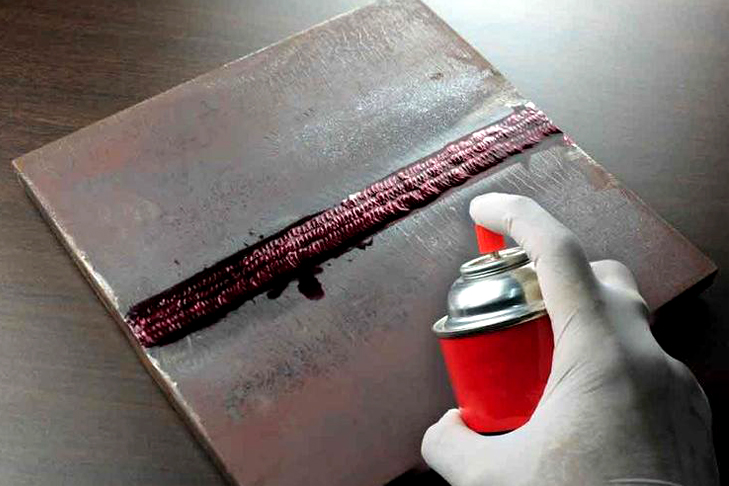

Penetrant Testing (PT)

Surface breaking discontinuity inspection of welding, casting, structural members etc.

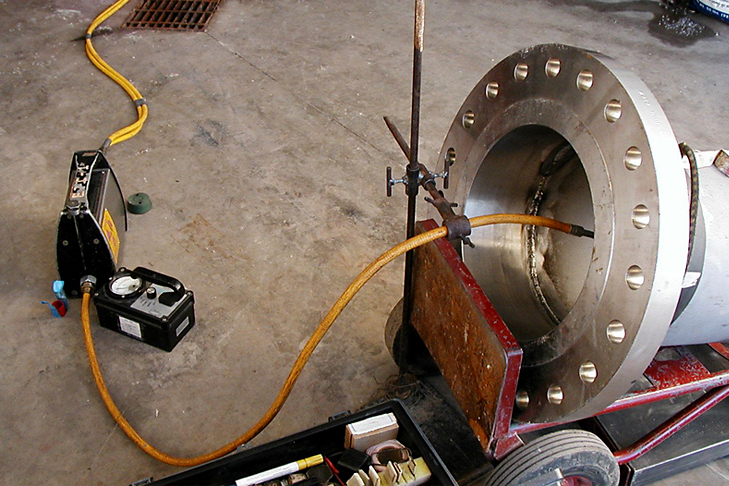

Gamma Radiography Testing (RT)

Gamma ray inspection piping, pressure vessels, castings with Iridium 192, Cobalt 60 & Selenium 75.

Visual and Optical Testing (VT)

Remote camera and video inspection of difficult access areas like piping and pressure vessel internals.

X-ray Radiography Testing (RT)

X-ray inspection systems are required to provide faster throughput and continuously demand for larger fields of view.

Magnetic particle Testing (MT)

Surface and near surface inspection on welding joints.

Request a Quote

Trust and Worth

Our Clients